Low energy consumption

Highest productivity

Low maintenance costs

Modular design

Increased safety & efficiency

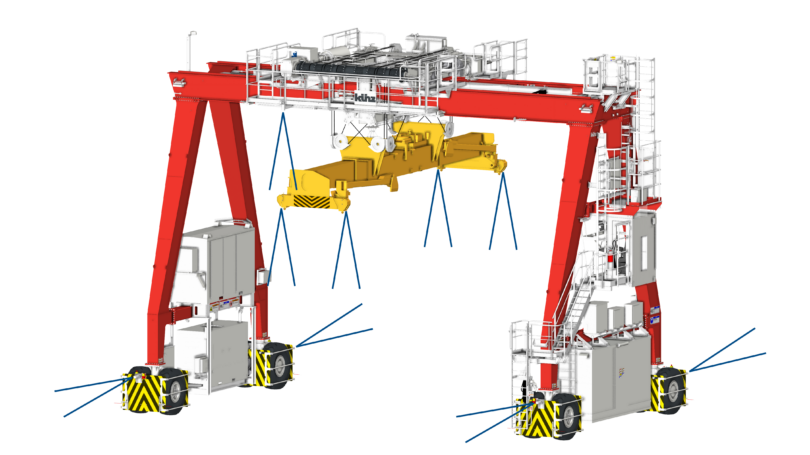

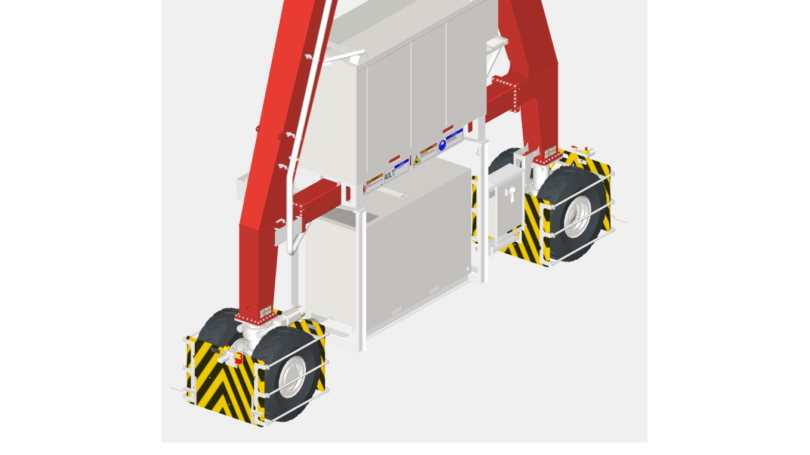

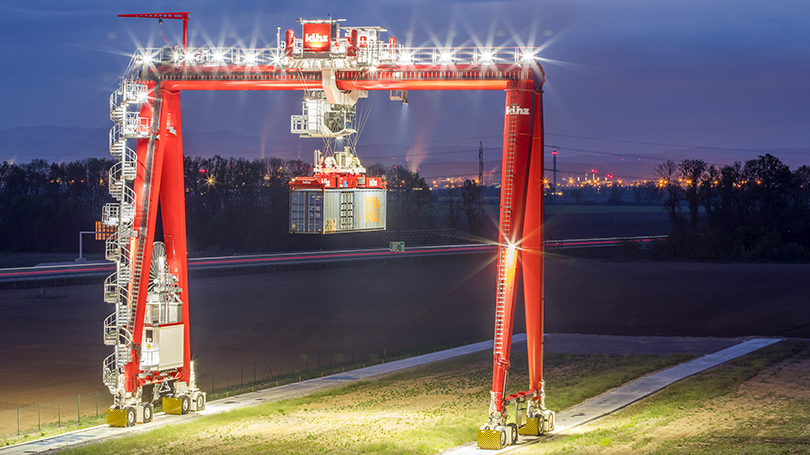

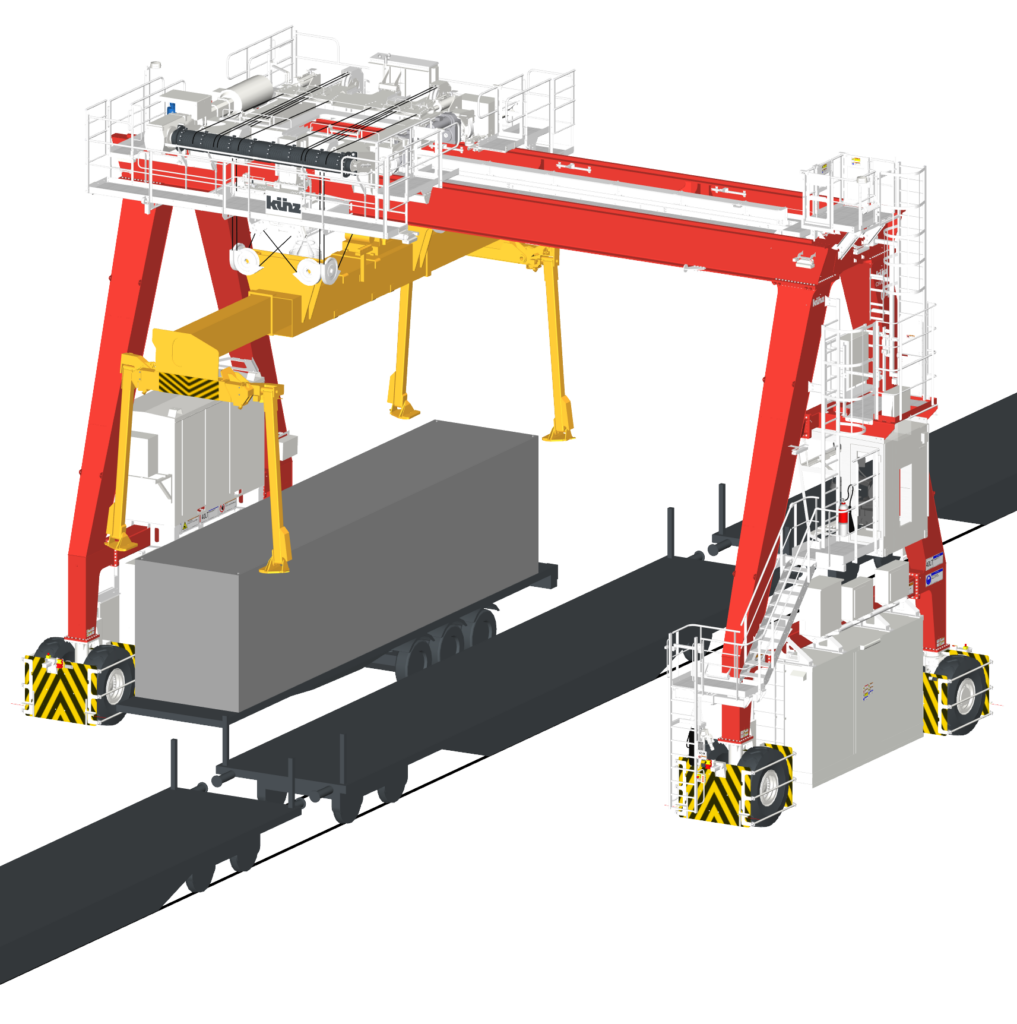

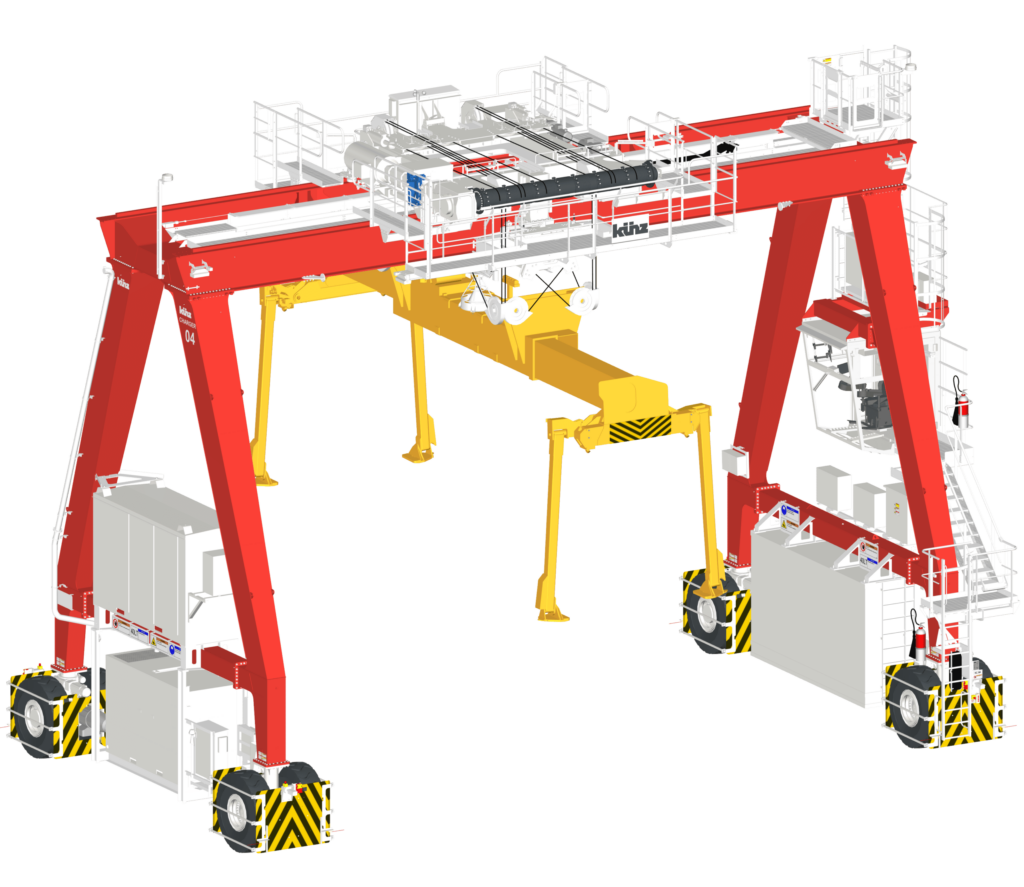

CHARGER – The new Benchmark FOR WHEELED OPERATION

Decades of experience and continuous product improvement have led Kuenz to become an innovative leader in the container handling market. Kuenz crane components are designed and selected with a focus on safety, availability, reliability, and efficiency. As a result of these strengths, Kuenz has developed the CHARGER.

Kuenz developed the CHARGER explicitly for the so-called wheeled operation or strip mode in intermodal terminals. Strip mode means the load units go directly from the truck lane to the train next to it – or vice versa. There is no ground stacking and, therefore, no gantry traveling with load required.

HIGHLY EFFICIENT, VERY SUSTAINABLE, TREMENDOUSLY Lower Energy and Maintenance Costs

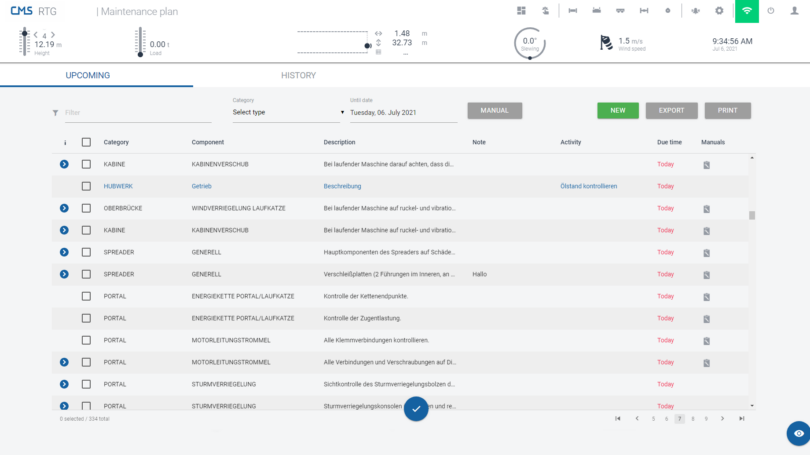

The fully electric-driven CHARGER is powered by an optimized hybrid system. As a source for charging the battery various options are available: low-capacity diesel genset, cable reel, conductor rail system, or others. As a remarkable result of the environmentally friendly hybrid solution, a significant reduction of energy consumption in comparison to a conventional diesel-driven RTG is realized. Kuenz focused on building a machine with minimized operational costs. Hoist, trolley and gantry are driven by highly efficient electric motors. Therefore, the typical disadvantages of hydraulic systems, like environmental pollution, poor efficiency, and high maintenance costs are eliminated. As a result, the CHARGER convinces with tremendously lower operational costs compared with similar equipment available on the market. Due to the hybrid power supply and the highly efficient drive system, the overall energy costs are reduced by up to 70%. Furthermore, the maintenance efforts can be lowered by up to 60%.

The Kuenz CHARGER features:

- Highly Efficient Electrical Drives

- Sustainable Power Supply Solutions

- Skew & Trim System Directly on Trolley

- Optimal Stiffness with 8 Inclined Ropes

- Prevention of Sway Movements

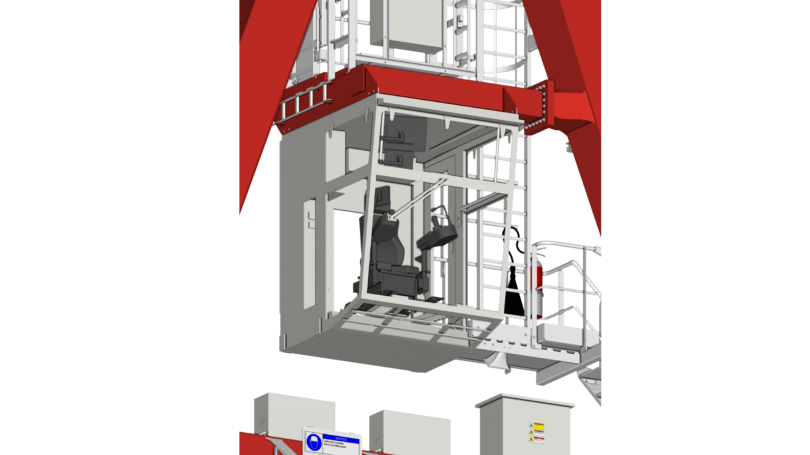

- Ergonomic Cabin with Optimal View

- TOFC (Piggyback) and WTP Operation

- Reduction of Energy Costs by up to 70%

- Reduction of Maintenance Costs up to 60%

Technical Data / CHARGER:

| Lifting capacity | 40,6 t | 40 LT |

| Crane span – standard | 10 to 16 m | 30 to 52 ft |

| Crane span – optional | up to 21 m | up to 70 ft |

| Wheel base | 8 m | 26 ft |

| Hoisting height above ground | 7,6 m | 25 ft |

| Skew | +/- 2,5° | +/- 2,5° |

| Trim | +/- 1,2° | +/- 1,2° |

| Hoist speed with full load | 0 – 12 m/min | 0 – 40 ft/min |

| Hoist speed with partial load | 0 – 25 m/min | 0 – 85 ft/min |

| Crane travel speed with full load | 0 – 20 m/min | 0 – 65 ft/min |

| Crane travel speed without load | 0 – 100 m/min | 0 – 330 ft/min |

| Trolley travel speed | 0 – 40 m/min | 0 – 130 ft/min |

SOLUTIONS

OTHER PRODUCTS

Do you have any questions or do you need a customized solution?

After decades in the industry, Kuenz understands that every project is unique. Technical requirements, local regulations and hundreds of other variables come into play. That’s why we don’t limit ourselves to off-the-shelf solutions and offer our clients a fully customized and tailor-made concept. We use the full range of our expertise to analyze the problem, design the solution and implement it in an efficient way.