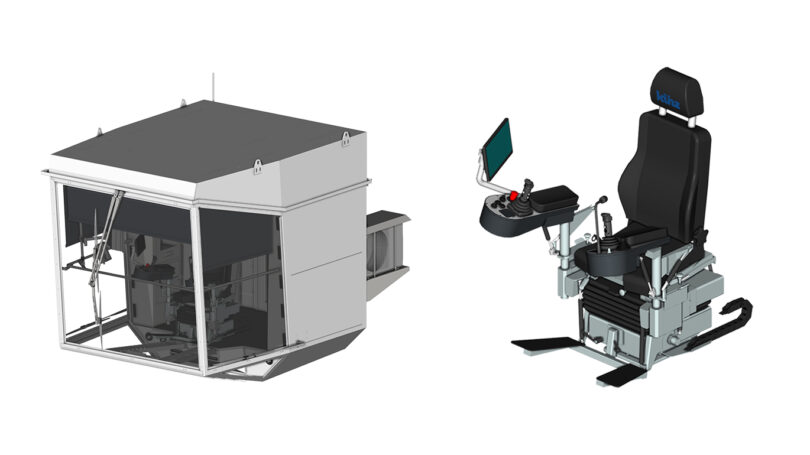

Unique aerodynamic design

Low energy consumption

Low maintenance costs

Highest productivity

KUENZ HIGH-PERFORMING LOG HANDLING CRANES. MORE EFFICIENCY AT THE LOG YARD

The aerodynamic gantry cranes from Kuenz increase the efficiency at the log yard significantly. For example, the crane system is the perfect link between the log sorting line and the task at the sawing line. These cranes are also ideally suited for other tasks and industries. The unbeatable performance compared to conventional equipment and the optimal use of space are essential advantages. The cranes also impress with their extremely long service life, combined with very low maintenance and operating costs, as well as CO2-neutral operation.

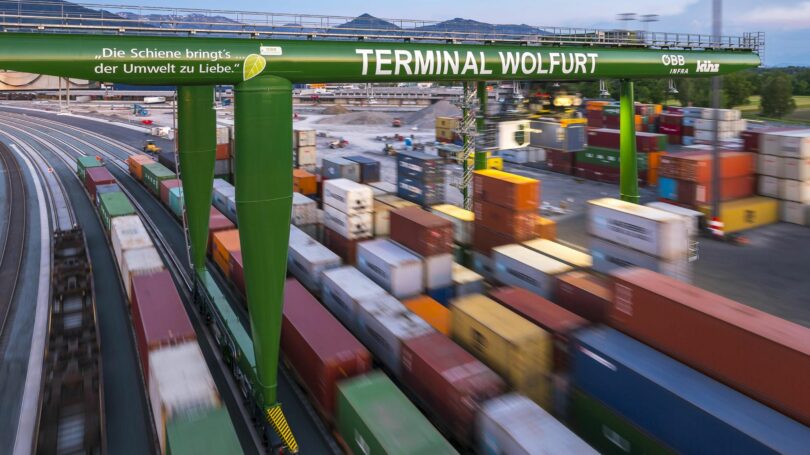

SOLUTIONS

OTHER INDUSTRIES

Do you have any questions or do you need a customized solution?

After decades in the industry, Kuenz understands that every project is unique. Technical requirements, local regulations and hundreds of other variables come into play. That’s why we don’t limit ourselves to off-the-shelf solutions and offer our clients a fully customized and tailor-made concept. We use the full range of our expertise to analyze the problem, design the solution and implement it in an efficient way.